Validation and Calibration in Raman Spectroscopy. Enhancing Raman Precision Through Peak Fitting Analysis.

ELODIZ provides consultation services to other Raman manufacturers and often we discuss the level of accuracy required to do an insturmetn calibration. Particularly, some engineers to not see the add value of measuring extremely precise peak positions, that are well below the spectral resolution of a given spectrometer or device. That is a mistake, as any error introduce at this level of calibration of a new device, exponentially impact future data that we will obtain with such device. We have recently published with our partners under the CHARISMA2020 EU project a new paper to evaluate this process.

Raman spectroscopy has a major challenge still today in the lack of standardized calibration protocols that are rcognised and used by allmanufacturers, particularly for spectral axis calibration, which complicates data harmonization and comparability.

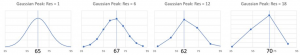

Fig 1. peak maximum is affected by number of pixels.

This white paper presents insights from an interlaboratory study conducted with a series of Raman spectrometers (for info, please refer to the publication DOI, at the end), focused on minimizing wavelength calibration uncertainty through optimized peak fitting of reference material spectra.

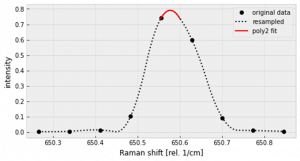

Fig 2, Peak fitting assures a reproducible and consistent results.

The study investigated four reference materials—neon, silicon, calcite, and polystyrene—using multiple peak models including Gaussian, Pearson IV, Voigt, and Lorentzian. Results indicated that certain peak models are more suitable for different materials: Gaussian for neon, Pearson IV for silicon, Voigt for calcite, and Voigt again for polystyrene.

A key finding was the significant influence of the signal-to-noise ratio (S/N) on calibration accuracy. The study recommends a minimum S/N of 100 for Raman peaks used in calibration, as lower S/N levels substantially increase uncertainty in peak position and width.

Additional factors influencing peak shape, such as sample properties, instrument configurations, and spectral resolution, were examined. The study stresses that improper peak fitting can introduce errors that propagate through the calibration process, negatively affecting subsequent applications like multivariate analysis, quantitative analysis, and machine learning models. This issue is particularly pertinent for portable and handheld Raman devices, which often operate with lower resolution and S/N.

Practical Applications and Case Studies

The study’s findings have significant practical implications for sectors relying on Raman spectroscopy:

-

Pharmaceuticals: A leading generics manufacturer applied the recommended calibration protocol using polystyrene standards and Voigt peak fitting. This approach minimized batch-to-batch spectral variability, resulting in improved quality control and enhanced regulatory compliance.

-

Polymers and Materials Science: A polymer research laboratory calibrated their Raman systems using silicon and calcite references. This improved calibration enabled more precise detection of phase transitions and crystallinity in composite materials.

-

Environmental Monitoring: Field teams employing portable Raman devices for microplastic detection adhered to the guideline of maintaining an S/N > 100. This adjustment significantly improved the reliability of spectral identification in challenging low-light, high-noise field conditions.

-

Forensics: Law enforcement agencies utilized the calibration strategies to enhance the reproducibility of Raman spectroscopy data for substance identification, bolstering the evidentiary value of the results in forensic investigations.

These case studies illustrate how standardized calibration practices can elevate Raman spectroscopy from a highly valuable tool to a robust, reproducible analytical method across diverse industries.

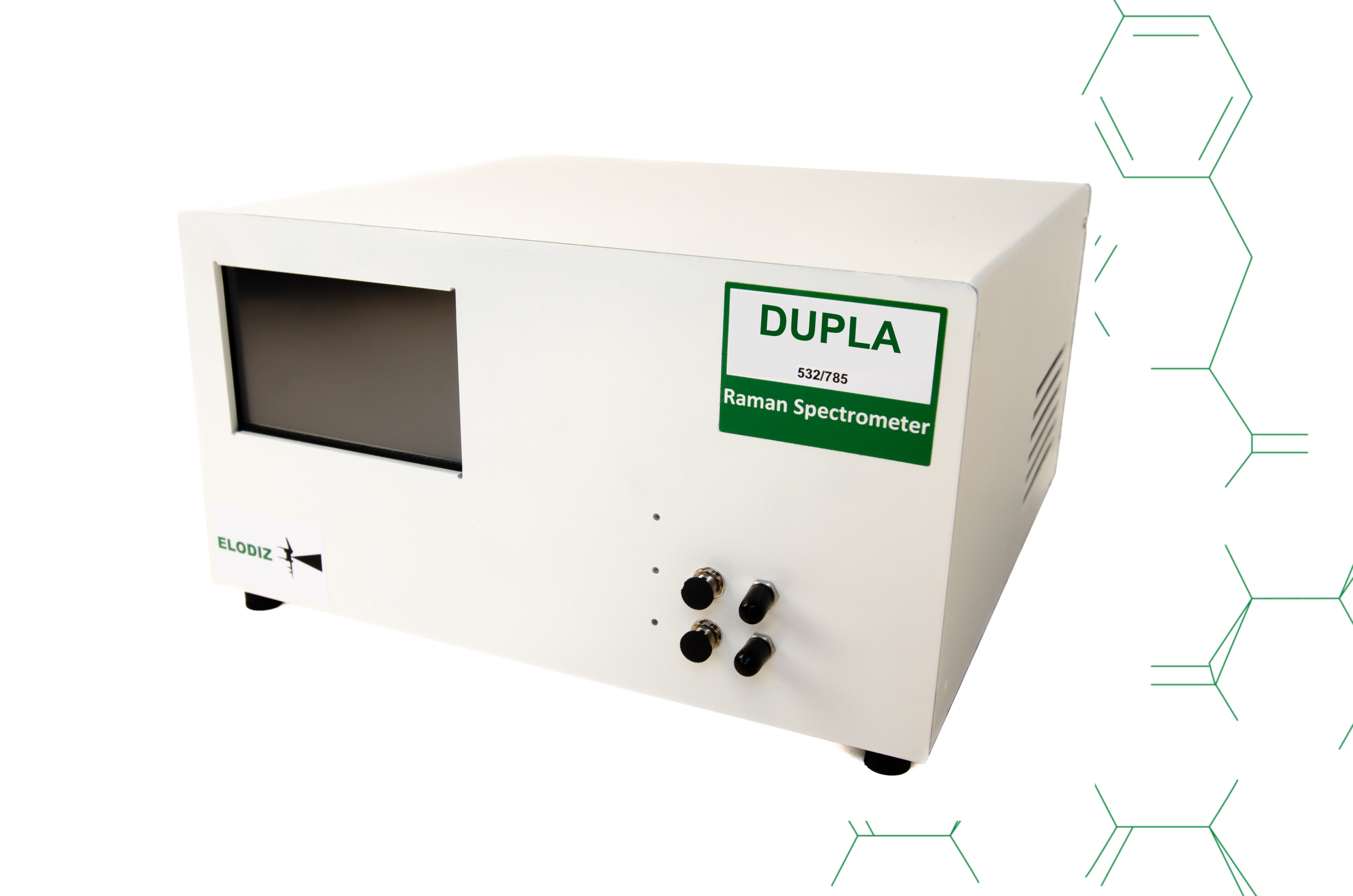

ELODIZ NEEGALAM RAMAN System, operating at 532 or 785, simultaneously in the same device,

ELODIZ supports your demand in outstanding calibration materials. OUR Raman products (UNIKA, DUPLA, NEEGAL and TRIPLA) are all calibrated used these protocols and guidelines

Acknowledgment: This work is based on the findings and recommendations from the study published in Journal of Applied Spectroscopy, DOI: 10.1177/0003702825133065 by the CHARISMA project, which has received funding from the European Union’s Horizon 2020 research and innovation program. the information is under (C) terms